Metal Casting Services

contact us

One-stop metal casting services

Are you looking for a manufacturing expert who specializes in metal casting supplies to assist with your casting projects? You are more than welcomed to leave your contact info and we will be in touch shortly.

Contact Information

Omnidex (China Office)

- Room 503, Floor 5, Rongxi Business Center, No.713 Jiangnan Boulevard South, Haizhu District, Guangzhou, P.R. China 510277

- +86 20 8388 7080

- info@omnidexgroup.com

Omnidex Ltd. (UK Office)

- +44 (0) 776963 3868

- uksales@omnidexgroup.com

metal casting supplies | Metal Casting Services | Industrial Manufacturing Services

Check out our Amazing Metal Cutting Projects and Ideas that Inspire you

8 Key Metals Used in Metal Casting

Metal casting is a highly versatile method for manufacturing complex geometries and high-performance components. You can determine the quality and durability of your metal cast component by choosing the right metal for your component. Read on to find out which metal is the best for your manufacturing requirements and learn more about the most commonly used metals for metal casting.

Tooling Design for Investment Casting

When it comes to metalcasting and CNC machining, tooling refers to reusable items that are utilised for each job. Wax-injection dies are used as tooling to create wax patterns in investment casting. If you know how investment casting works, you already know that the investment casting process relies on these wax patterns. Wax has smooth surfaces, low melting temperatures, and excellent flow properties enabling highly complex investment castings to be made.

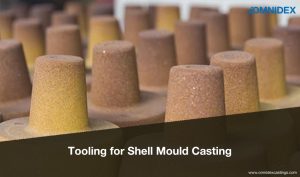

Tooling for Shell Mould Casting

Tooling for metal casting processes varies. From sand castings with individual moulds and cores to shell moulds with a variety of pattern plates, core boxes, cavities, ejection systems, and gates. When all of these components come together, the shell mould casting process allows the foundry to precisely produce the required dimensions, whether it’s doing a run of 100 or 100,000 parts. There are a variety of metal forming techniques that can be used to create the mould tooling for shell mould casting, and the best process is determined by the conditions of the foundry.

Aluminium Casting vs. Steel Casting: Which Alloy is Right for Your Product

There are a variety of materials that can be used for casting, with steel and aluminium being two of the most popular. Their strength, durability, and aesthetic appeal make them ideal for casting. Manufacturers rely on the properties of these two materials to produce the products they need.They both have advantages and disadvantages. Despite this, manufacturers still prefer them because of their good properties. It is helpful to compare them to find out which is a better alternative…

An Overview of Green Sand Casting

Casting metals in foundries as a mold is done with green sand, a material that is a compound mixture of sand and cement. It is known as ‘green’ not by its colour, but rather because the metal is not ‘set’ when it is poured into it; rather…

Your Trusted Industrial Manufacturing Experts

Check out our Amazing Metal Casting Projects and Ideas that Inspire you

Aluminum Manifolds

OMNIDEX aluminum manifolds provide a convenient junction point for the distribution of fluids or gases. Visit here to find out more about how OMNIDEX can make high quality and defect free aluminum manifolds using gravity casting. Contact us for custom manifolds.

Sand Cast Brackets

OMNIDEX’s professional manufacturing team carefully controls and produces our custom sand cast brackets during the sand casting process to reduce shrinkage porosity and other issues for our customers, which further ensures the best quality.