We are always ready to help with your latest metal casting project.

Contact our Customer Service and let us know how we can help to catapult your next project to success.

In order to guarantee optimal outcomes for each casting project and the product development process, Omnidex Casting utilizes a variety of technology-driven processes. We know each project is unique and comes with its own set of challenges, so we offer bespoke casting designs that will produce the optimal result.

Upon receipt of your order, our in-house engineers will evaluate the project and determine the most suitable product development and solution approach for your project. We work closely with our customers to develop each part or idea into a production optimised, functional and cost-effective delivery.

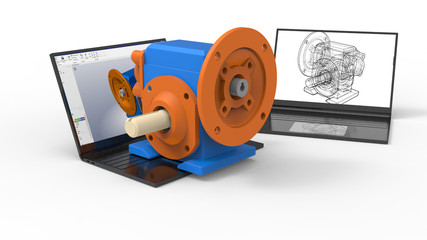

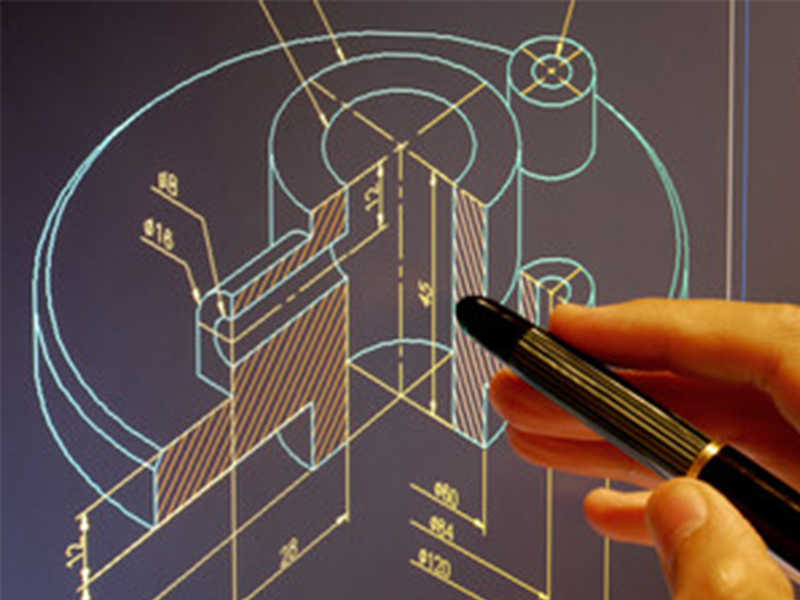

Using our many man-years of real-life experience we can advise on the most appropriate process for your product and, using 3D CAD and advanced simulation software, we provide a properly engineered solution.

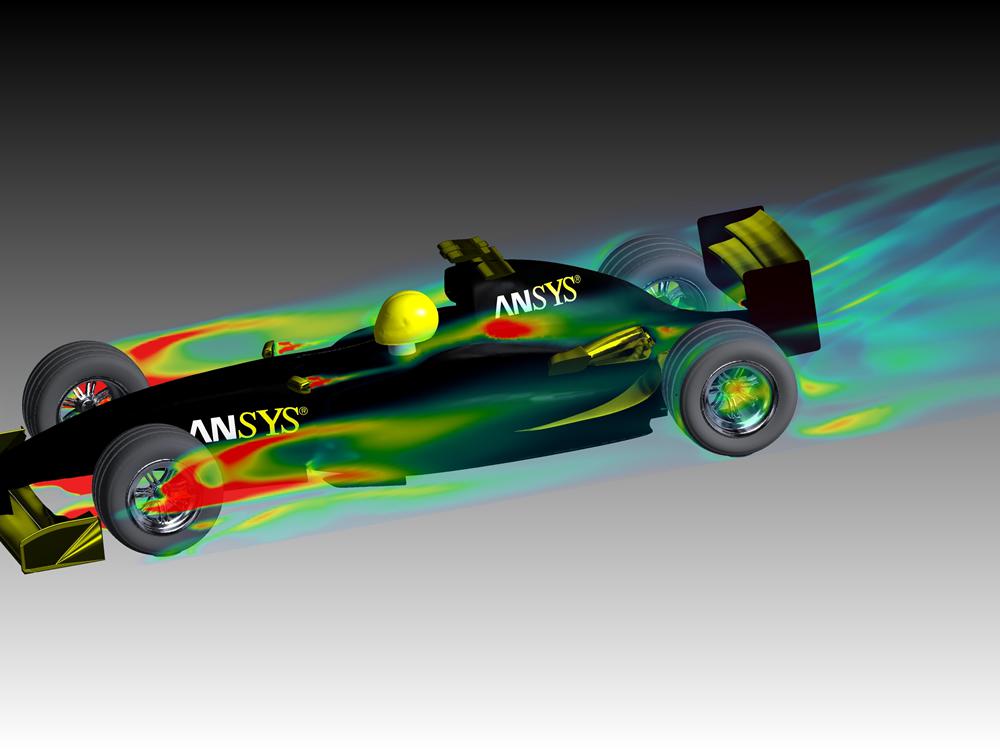

The design phase is crucial to the production of quality metal cast parts. This involves the creation of 3D CAD models and discussion with the customer’s team to ensure fit and function are clearly understood. The application of 3D simulation software enables us to develop the design with the highest possible integrity and has been proven over many projects to produce top-quality castings.

In the review phase, a detailed analysis is carried out by our engineers. The review phase includes (but is not limited to) the following items:

This proactive approach enables us to develop and optimise the part with consideration to weight restrictions, function requirements and mechanical properties such as elongation, tensile strength and hardness, whilst not losing sight of the commercial constraints.

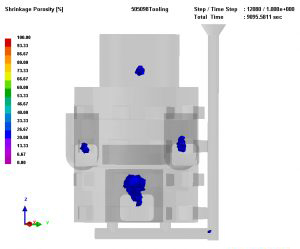

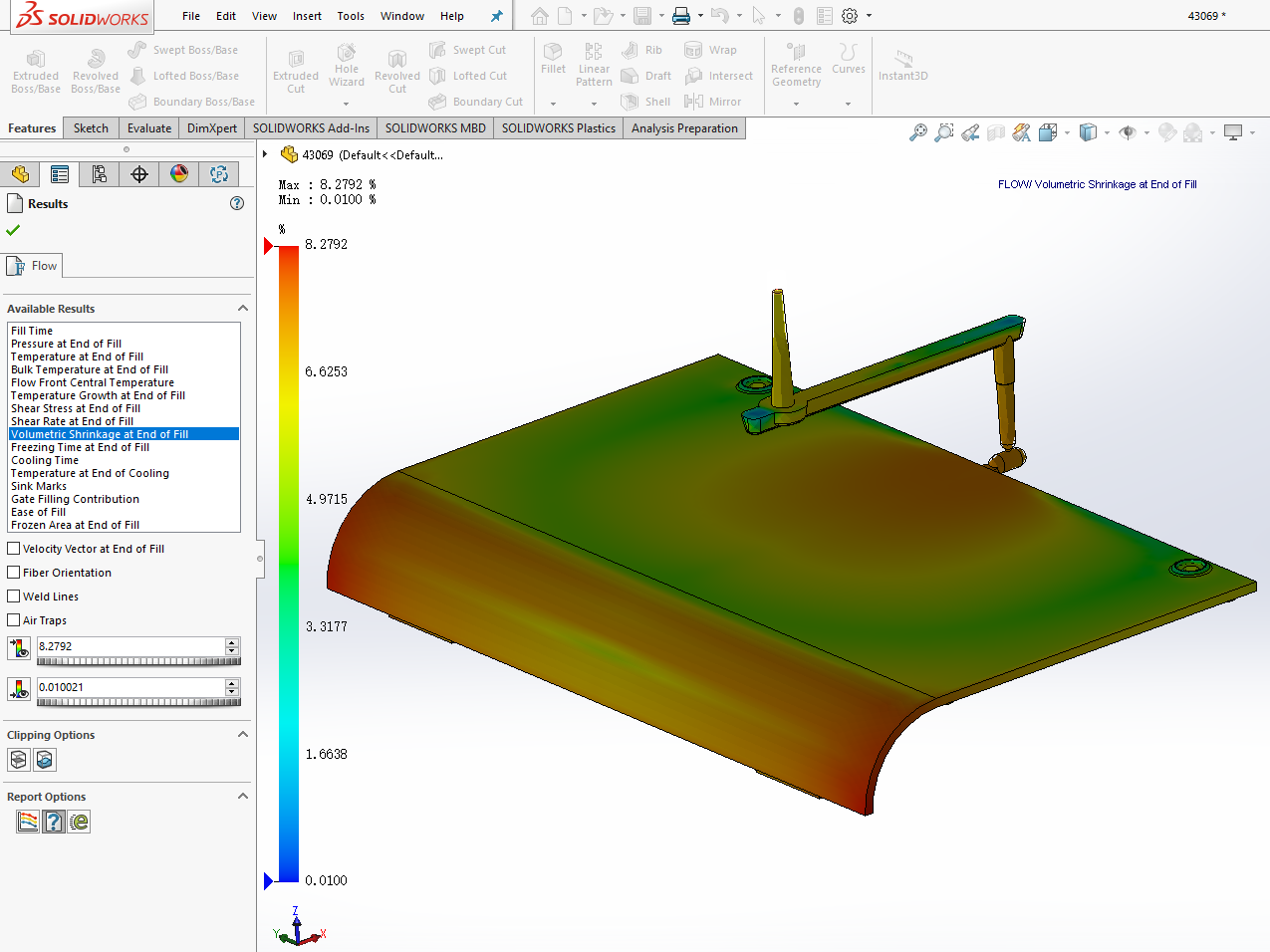

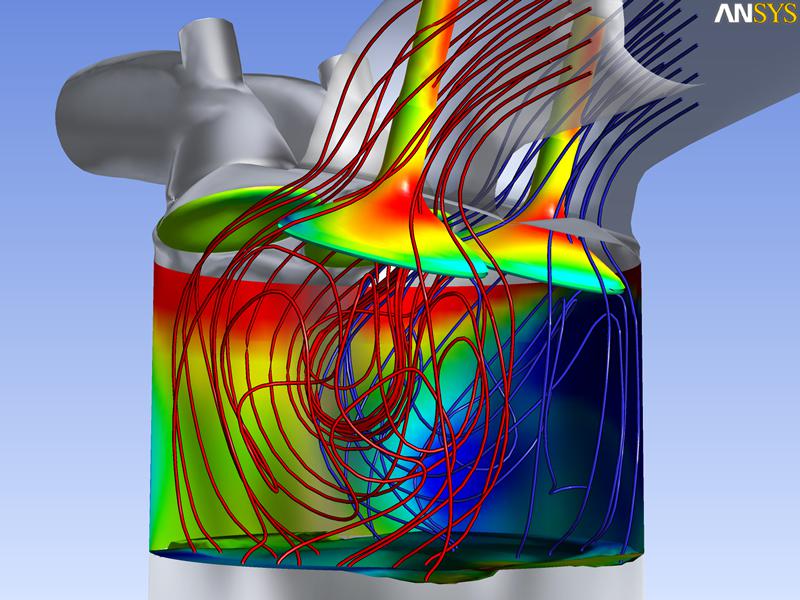

Our bespoke 3D simulation software is applied to all new jobs and is proven to produce castings with extremely high cast integrity. This ensures that quality is maintained.

Simulations permit or design team to:

We repeat simulations until we achieve the highest standard result. Communication and input from the customer are essential at this stage as occasionally changes are required to optimise the design to achieve the best casting integrity, highest benefits and production cost savings.

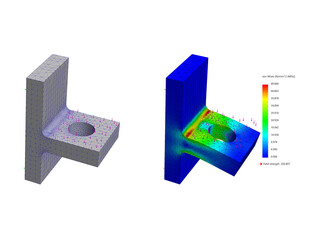

To ensure that casting designs meet minimum function requirements, finite element analysis (FEA) can be used to examine loading effects on specific areas of the part. This is especially useful when comparing different metal casting processes and enables localised changes to overcome identified issues.

Due to Finite Element Analysis, we can :

Our Engineering Team uses specialised software tools in the product design & product development processes, including:

You can trust Omnidex for your metal casting projects. Among the metal casting expertise that we offer are:

Our differentiated combination of engineering expertise, cutting-edge technology, and supply chain management ensures client satisfaction and quality.

For a free quote on your next precision machined parts order, contact our casting experts today.

Contact our Customer Service and let us know how we can help to catapult your next project to success.

If you are looking for metal casting services, our brochure is a great way to discover what Omnidex has to offer. You can download HERE or EXPLORE HERE to learn more.

Copyright © 2022 Omnidex Group. All rights reserved.

This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Strictly Necessary Cookie should be enabled at all times so that we can save your preferences for cookie settings.

If you disable this cookie, we will not be able to save your preferences. This means that every time you visit this website you will need to enable or disable cookies again.