Case Study:

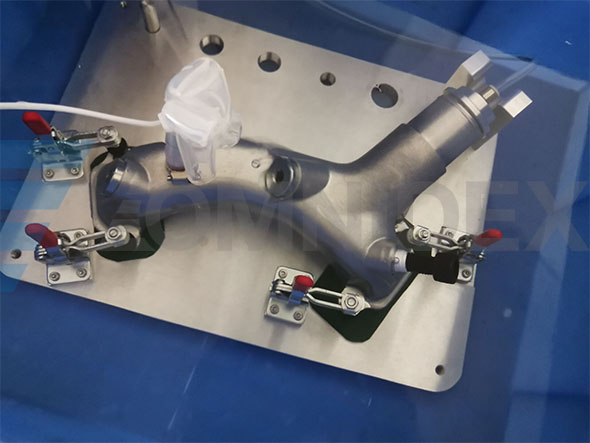

Improvement in the Quality of the Aluminum Manifolds made from Gravity Casting

The problem part in question was a manifold, a major component in vehicles. Gravity casting is used to make these Aluminum Manifolds. Machining and polymer infiltration processes are also used in their manufacturing.