We are always ready to help with your latest project.

Contact our Customer Service and let us know how we can help to catapult your next project to success.

casting sand casting materials

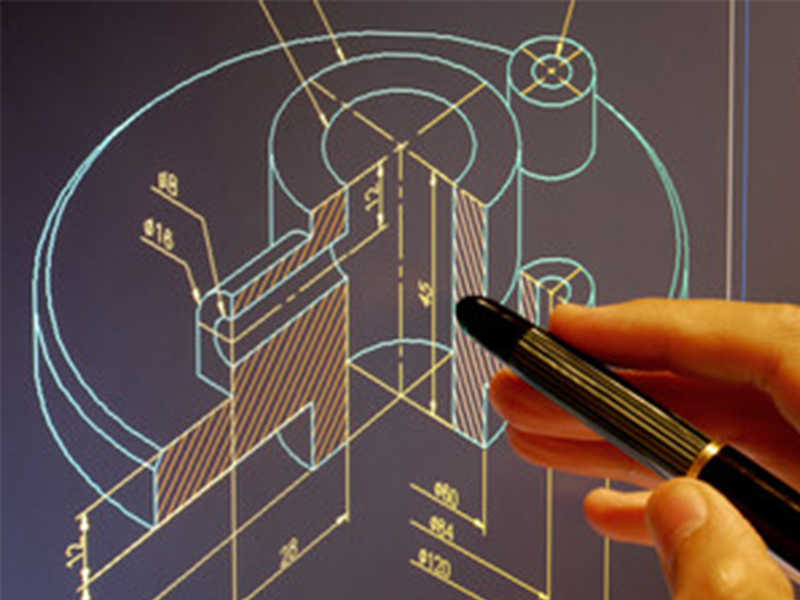

Planning is critical in any kind of manufacturing operation. However, when it comes to CNC machining, it becomes supercritical. CNC machining is a relatively costly process and therefore designers must understand the operation in order to minimise costs. Without a good understanding of the CNC process and the factors that influence the cost of the machined part, designers can not simplify the operation whilst maintaining the functionality of the part.

This article will review some of the key factors that could impact the CNC manufacturing cost.

The selection of the material in CNC machining influences the cost of the part both in the cost of the raw material and the material machinability cost – some materials are more difficult to machine as compared to others. Furthermore, some materials need extra safety precautions during machining and this increases the overall machining cost.

In CNC machining, it is recommended that the design should be simple. The cost of the machining is directly related to the complexity of the design; the more complex the part, the higher the cost. For example, some parts may have small features such as holes or slots, or they have multiple faces to be worked on. In such cases, the machining cost of the part will be higher as extra time is needed to change the tools or other operational setups.

Inaccurate and incomplete CAD files may also increase costs during manufacturing. In such cases, orders would be delayed as designers have to correct the CAD files which increases the overall machining cost of the part.

CNC machining demands skilled labour. More complex parts require highly trained and skilled machinists. The addition of experts and trained machinists increases the cost of the job.

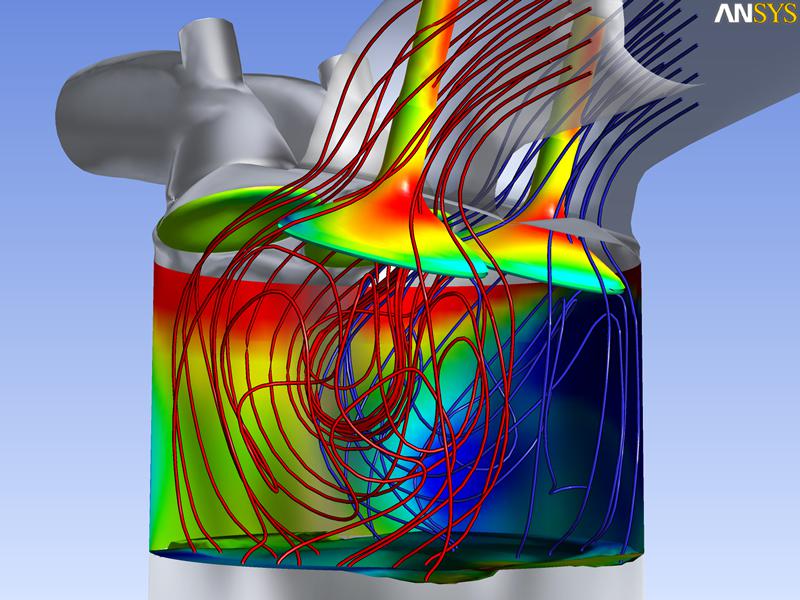

CNC machines have different operational capabilities and they have different prices. For example, some parts can be made on one multi-axis machine, others will need multiple machines. So, the part cost depends on how many different machines and operations are needed to machine it. The size and capability of the equipment needed will add to the factors that influence the overall cost.

Part tolerances specify how close the part dimensions should align with the original design. If the tolerances are tightly specified, then the overall cost of the machining will increase.

If a part requires additional treatments after machining, these also impact the cost. These treatments include heat treatments, specialized coatings, anodizing, surface finishing, and other speciality machine operations.

The quantity of the ordered parts will also affect the unit cost of the part. For instance, If the order quantity is small, then the CNC machining cost would be higher. But if the order quantity is higher, then per unit cost can be lower.

At Omnidex, we consider all the above factors while determining the cost of a CNC machined part. Our team works to reduce the cost by, for example, alternate material selection and modifications to the design. Design is the crucial factor from the manufacturer’s end as a simple and efficient design helps to reduce the per-unit cost of the CNC part.

mechanical properties

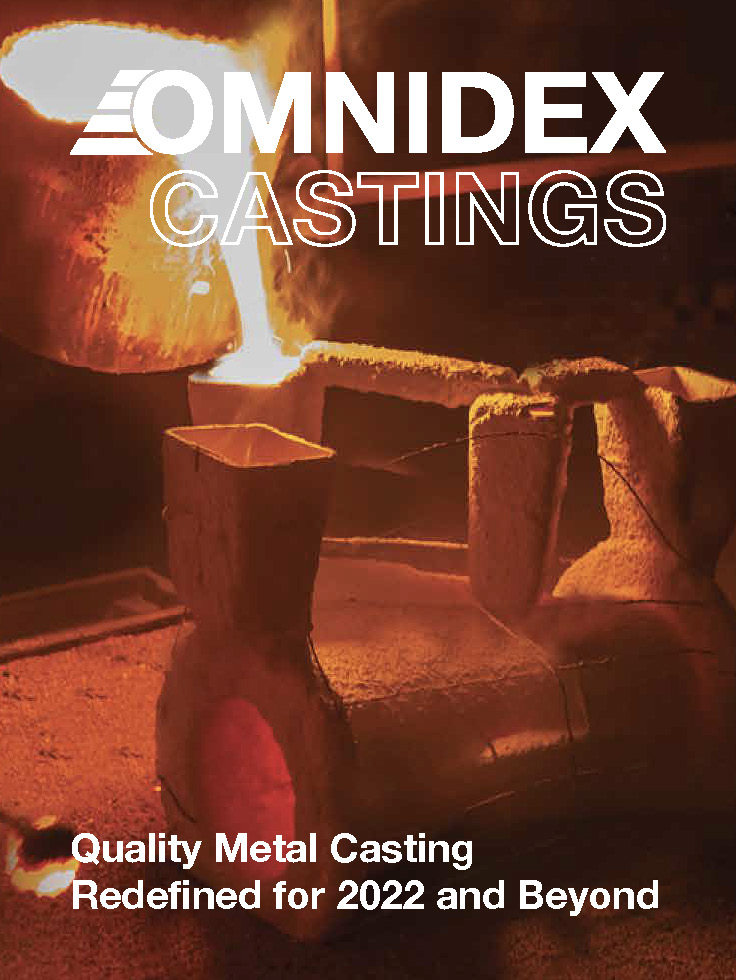

Omnidex is a World-Class Manufacturing and Engineering company that produces high quality, porosity-free casting products which are trusted by companies across different industries. Throughout the whole process, from product development to delivery, we strive to provide you with unwavering support. Providing you with unmatched diverse capabilities and experience, we help you overcome any obstacle.

Contact our Customer Service and let us know how we can help to catapult your next project to success.

If you are looking for metal casting services, our brochure is a great way to discover what Omnidex has to offer. You can download HERE or EXPLORE HERE to learn more.

Copyright © 2022 Omnidex Group. All rights reserved.

This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Strictly Necessary Cookie should be enabled at all times so that we can save your preferences for cookie settings.

If you disable this cookie, we will not be able to save your preferences. This means that every time you visit this website you will need to enable or disable cookies again.